TigerScan

Call Today! 800-443-2222

Or stop in for more details about this and other products we offer!

Product Description

If you think oil is expensive, try a 55 gallon drum of mixed hardwood scrap! You probably paid in the range of $278 to $340 for that material by the time it hits your cut-off saw! Makes oil look cheap doesn’t it? How would you feel if your dumpster had 1/3 less scrap in it from your cut-off saw?

TigerScan optimizes your material, counts your pieces, and gives you the right length, in the right quantity, with minimum material, waste and labor.

Benefits:

- Faster, more reliable than crayon marking

- The least material used

- The right number of parts, not more, not less

- Dramatically reduces labor

- Dead-on part sizes

- Clear, easy to read labels

- Eliminates re-work

- Powerfully balanced optimization for true optimized results

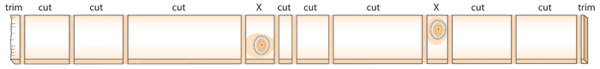

Do your cut boards look like this? If not – you are throwing money away!

| TigerScan Specifications: |

|

| Positioner | See TigerStop Specifications page |

| Positioning Accuracy** | +/- 0.004″ (+/- 0.1mm)* Interferometer verified upon request |

| Power: | 120VAC @ 8amps |

| Power Requirements: | TigerStop: 120V-220V, 50Hz-60Hz, isolated (220VAC on special request) Laser Scan: 115VAC @ 2amps – May be on same circuit as TigerStop |

| Accuracy Validation |  National Institute of Standards and Technology certified National Institute of Standards and Technology certified |

| Productivity | Productivity is an estimate. Actual productivity depends upon speed of cut cycle, feed speed, accuracy requirement, and condition of material. Feeding stock of 8′-12′ one piece at a time, 12,000 lineal feet (3650 lineal meters) to 16,000 lineal feet (4900 lineal meters) per shift with part size average of 24″, using 18′ working length machine.

You may actually produce more or less based upon multiple factors. Test runs of specific materials (to be supplied by customer) can be done at the factory for no charge. Contact TigerStop for details and scheduling |

| Network Options | ethernet, serial, USB |

| Standard Software | Optimization Package and WorkFlow Manager (Office connectivity, download and reporting) |

| Optimization | True optimization upgrade with user configurable weighting for best fit / highest value / longest first |

| Reliability Testing | HALT/HASS certified (Highly accelerated life testing / stress screening) TSI (Thermal stress imaging) |

| Electrical / Safety Certifications |  TUV Rheinland North America, meets or exceeds TUV Rheinland North America, meets or exceeds   standards standards |

| Environmental Certifications |  RoHS compliant, RoHS compliant,  lead-free, lead-free, waste electrical and electronic equipment waste electrical and electronic equipment |

| Warranty | 12 months. Extended warranty options available at extra charge. |

| Country of Manufacture | United States of America |

| Technical Support | Full-time phone support 6 am ~ 4pm Pacific Time, M-F; factory-certified technician available |

| Customer Satisfaction | 95% or greater

|

* The truth about part accuracy: Your actual part accuracy will depend on a number of factors outside of TigerStop LLC’s control. This includes but is not limited to condition and type of saw blade, speed of cut, clamping options selected for the machine, material type, material straightness and internal tension of the material, feed speeds, temperature and moisture of the product being cut will all affect your quality and the accuracy of cuts. Also, we have found that there are distinct differences in measuring devices used to validate dimensions of cut parts that can affect apparent accuracy. These factors will affect all cut off systems, regardless of the manufacturer.